AUTOMATIC STRETCH WRAPPERS

GET EQUIPPED TO TAKE YOUR BEVERAGE BUSINESS TO THE NEXT LEVEL

When beer & beverage sales are booming keeping up with demand can be difficult. Orion understands the challenge you face to improve efficiency and throughput. Orion’s fast, reliable, hardworking automatic stretch wrappers are tailored for beer and beverage operations. So, you can increase speed, efficiency, and profitability without increasing your personnel.

FAST: FLEX HPA HIGH PROFILE AUTOMATIC

Pick up the pace with Flex HPA Automatic stretch wrapper and perform the entire wrap cycle automatically. Repeatable, safe, and secure loads, plus improved speed and load containment not possible when wrapping by hand. Simply place the pallet load on the machine and pull the lanyard switch while backing away. Every load is securely wrapped using programmed wrap patterns. Orion’s load stabilizing Insta-ThreadTM film delivery system and 260% powered pre-stretch maximize the film stretch and strength properties, while using the least amount of stretch film.

FASTER: RTA ROTARY TOWER AUTOMATIC

Crank up throughput another notch with the RTA Rotary Tower Automatic stretch wrapping system. Because the RTA rotates the film carriage around a stationary load, it’s ideal for quickly wrapping even the most difficult loads, including fragile, unstable, light, or extremely heavy loads. There’s no weight limit as loads are wrapped while sitting directly on the floor. Start the cycle with hanging lanyard and move on to the next load.

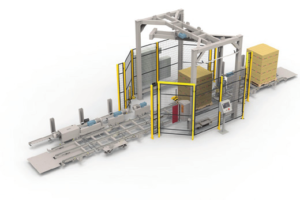

FASTEST: MA-DX LOPRO

The MA-DX and LoPro drag chain triple-strand conveyor work together as the ultimate pallet wrapping system for high volume applications. The 60 feet-per-minute LoPro conveyor keeps pace with the MA-DX’s 28 RPM counter-balanced rotary arm wrapper. Eliminating ramps and rollers ensures unwrapped load stability, and the user-friendly 4” pass height makes the LoPro safe and efficient for loading with a pallet jack, electric walkie or forklift. Convey up to three 2,500-pound pallets at a time. The LoPro automatically separates pallets, wraps each individually, and re-consolidates for pickup. An integrated digital scale verifies pallet load accuracy.

FULL THROTTLE: MA-DX2 LOPRO

Using the LoPro conveyor with Orion’s dual arm – dual carriage MA-DX2 kicks high-speed performance up to another level. Using two 30” Insta-Thread™ film carriages and 28 RPM counter-balanced rotary arms, the MA-DX2 pushes load throughput to 100 pallets an hour. Opposing carriages apply film in a crisscross pattern that improves speed, and provides additional stability.