A SEAMLESS, HIGHLY PRODUCTIVE PICKING EXPERIENCE…The Cirrus Semi-Automated Case Picking System

CONVENIENTLY AND COST-EFFECTIVELY REPLENISH AND PICK ALL OF YOUR SKUS IN A CONDENSED PICK PATH WITH THE CIRRUS SEMI-AUTOMATED CASE PICKING SYSTEM.

Somewhere between full automation and no automation lies The Cirrus Semi-Automated Case Picking System. For distributors with a 2 to 8 million annual case volume size, The Cirrus Semi-Automated Case Picking System is a perfect fit. This less costly alternative has ROIs in the 2-3-year range, provides a much more organized pick path, less full-time employees, overtime and turn over. All of our systems are customized for each client’s warehouse/distribution center and all designs are based off of Cirrus’ extensive evaluation of the client’s SKU profile and order data.

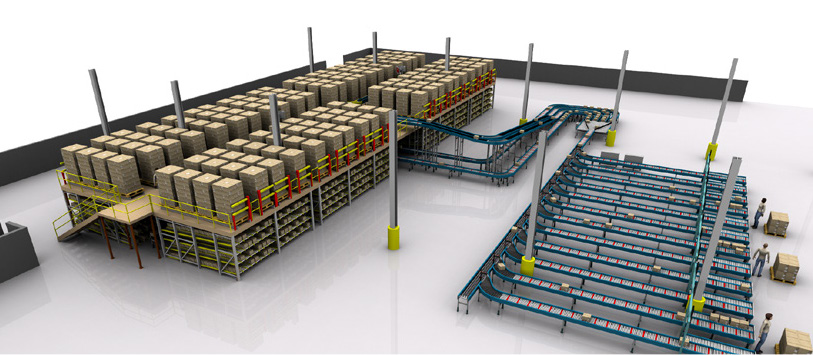

Cirrus designed this revolutionary picking solution that focuses on conventionally picking the top 50 – 125 SKUs while having different load builders pick medium to lower moving SKUs from a multi-level pick module. After all the high-volume SKUs are picked, the conventional pickers top off their pallet of orders at the downlines where all the roduct, that was picked in the pick module, is waiting for them.

FEATURES AND BENEFITS OF THE CIRRUS SEMI-AUTOMATED CASE PICKING SYSTEM:

• A lower total cost of ownership vs. a fully automated case picking system

• Ability to handle thousands of SKUs efficiently with the flexibility for SKU growth

• Design layout that will optimize picking and provide better organization for the warehouse

• Multi-level pick modules with mezzanines, conveyor, case flow, and full pallet picking

• Condensed pick path consisting of high-volume SKUs

• Downlines placed near the end of the pick path and stretch wrappers

• Can easily incorporate Cirrus Quality Control Stations to automate the QC and stretch wrapping process

• Reduction in labor & hardware costs by reducing turnover, employees, and overtime

• Easier, safer, and healthier for load builders vs. manual picking

• Integrated with layer picking to optimize the build of starter pallets for load builders

• Significant reduction in pick path vs. traditional pick path

• Efficient replenishment process with closer proximity to back stock locations

• Greater picking accuracy through monitor displays & automated system feedback

• Fully integrated with your RAS

• 2-3 year ROI

Contact a Cirrus Tech representative today by clicking here, or download our capabilities brochure here