LDF Sales & Distributing markets, sells and distributes Coors, Miller, Boulevard, Red Bull and a full range of other beer, wine, spirits and non-alcoholic beverages in Kansas and Oklahoma and is committed to success and long-term profitability by consistently exceeding customer expectations and being the Employer of Choice of “Choice” people.

Author: Linnihan Foy

J.J. Taylor Distributing is a beverage distributor of high quality products such as MillerCoors, Pabst, Yuengling, and an array of quality imported beers. The company chose “The Crane” ASRS by Cirrus Tech and Cirrus Voice Picking to add efficiencies to its operations.

Foot Locker is a leading global athletic footwear and apparel retailer. Its stores offer the latest in athletic-inspired performance products, manufactured primarily by the leading athletic brands. Foot Locker offers products for a wide variety of activities including basketball, running, and training.

Eagle Distributing in Fremont, NE, distributes Anheuser-Busch products and many other high-quality beers and nonalcoholic products. Eagle Distributing has implemented “The Crane” ASRS by Cirrus Tech, Cirrus Warehouse Management System, and Cirrus Voice Picking.”

Cirrus Tech Inc. provides a wide range of products and services to help today’s retail distribution centers. The challenges to be efficient, accurate, and fast are greater now than ever before, and we can help you get there. Whether you’re looking to find the best way to pick orders or manage your inventory more efficiently, we are a company with the right answers, the right team, and the right products.

CLIENTS

Cirrus Tech Inc. knows the challenges that pharmaceutical and life science manufacturers face daily. These challenges include the need to store and track high-value products in inventory, to work in a secure environment, and the ability to streamline the order fulfillment process. We have systems to store, sort, and pick your product while meeting these challenges, and we can help you determine the best solution.

The beauty industry around the world is growing at an average of 5% per year, with the bulk being spent in Europe and America, while India and Asia are rapidly catching up on per-person investments into personal care.

With an industry that is growing through challenging economic times, it stands to reason that companies like ULTA, which provide personal care products, will have to manage growth. Cirrus Tech has been a proud partner with ULTA by providing state-of-the-art warehouse solutions that have helped them manage their business warehouse processes and procedures.

CASE STUDIES

Cirrus Tech Inc. is well-equipped to provide systems for direct-to-consumer operations. As an integrator offering best-of-breed hardware and software solutions, we are the right choice for your project. Storage Systems, Order Fulfillment Systems, Sortation Solutions; we offer the advantage you need to store your products, fulfill your orders, and get your orders out the door accurately and efficiently to ensure on-time delivery and complete customer satisfaction.

CLIENTS

Whether you need more space or are simply looking to become more efficient in how you process your orders, our Cirrus WMS, Directed Picking, Cirrus Automated Case Picking, and The Cirrus Tech Crane System solutions may be right for you.

By combining Proven Technologies with Seamless Integration, Cirrus Tech is ready to help your company reach the next levels of efficiency and profitability. There are not a lot of ways to significantly improve your bottom line on a year-by-year basis. We have several.

By making a commitment to the future of your company with the implementation of one of these solutions, you will absolutely save money on an annual basis, making your wholesale operation significantly more profitable, efficient, and competitive.

CLIENTS

- Adams Beverages

- Cherokee Distributing Company

- Eagle Distributing of Fremont

- Eagle Distributing Of Shreveport

- Eagle Rock Distributing Company

- Euclid

- Fisher59

- Gulf Distributing Company of Birmingham

- J. J. Taylor Distributing, Florida

- LDF Sales and Distributing

- Long Beverage

- New Hampshire Distributors

- Wilsbach Distributors, Inc.

CASE STUDIES

The Challenge

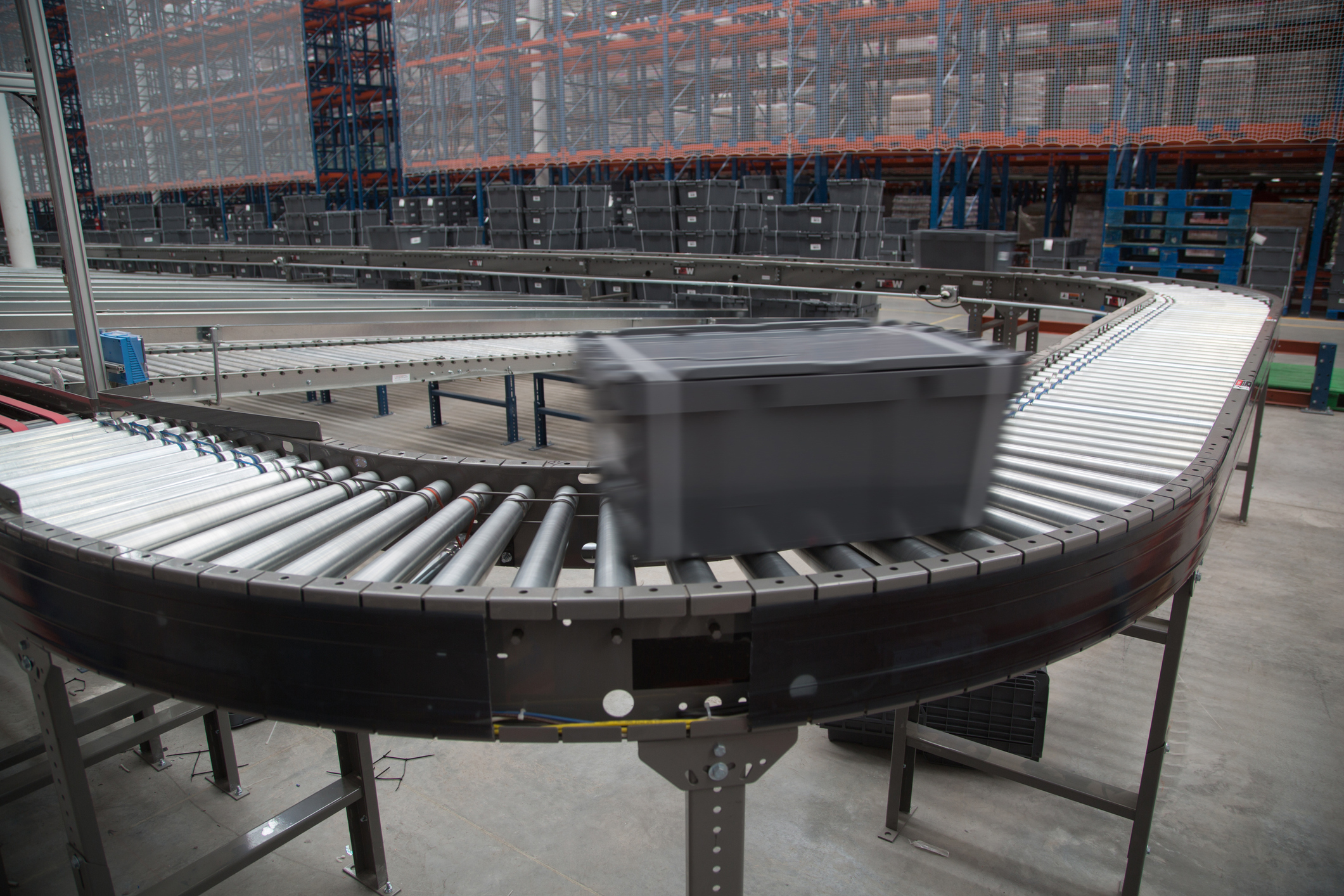

With 120 stores, Ollie’s Bargain Outlet is a storied company and is the Mid-Atlantic’s largest retailer of closeout, surplus, and salvage merchandise. Averaging about 40,000 containers per day in a facility that was not designed to house a state-of-the-art warehouse control system was no easy task.

The Challenge

With 120 stores, Ollie’s Bargain Outlet is a storied company and is the Mid-Atlantic’s largest retailer of closeout, surplus, and salvage merchandise. Averaging about 40,000 containers per day in a facility that was not designed to house a state-of-the-art warehouse control system, installing a fully customized Cirrus WCS was no easy task. When Ollie’s Bargain Outlet in Pennsylvania called upon Cirrus Tech to create and integrate a Cirrus Warehouse Control System (WCS) as well as Cirrus Programmable Logic Controls in their distribution center, the Cirrus Tech team rose to the task.

The Approach

At Ollie’s, the process begins the night before when all the carton labels are pre-printed for the pickers and packers. There are two main picking lanes, and each lane has two levels. The pick-to-light process in these lanes is vital to their operation. First, the picking lanes are stocked with the items going out that day. Once an operator scans the item, the light display reports how many items are required for each WAVE. Operators pick, label, and deposit the product onto the conveyor that will cart the item off to the spiral lifts. Once the spiral lift carries it to the second level, it then heads straight down the line to the lane merge.

Of the 4 merge lanes, individual lanes can be given priority over other lanes based on product flow, product type, barcode information, routing priorities, or as a first-in-first-out situation. After the merge, they are sent towards a barcode scanner just prior to the sorter.

Convincing Results

The Cirrus Inventory Control System and PLC software intelligently monitor these barcodes to allow Ollie’s Bargain Outlet to determine which shipping lanes each barcode is assigned to in the fulfillment system.

Our Cirrus WCS and PLC Software solutions enables Ollie’s Bargain Outlet to easily accommodate increases in orders, while utilizing automation to dramatically reduce handling and packaging costs. The result is a Cirrus WCS solution that meets the client’s growth expectations and dramatically reduces labor costs while increasing order fulfillment accuracy.