YOUR SINGLE SOURCE FOR A COHESIVE WAREHOUSE CONTROL SYSTEM

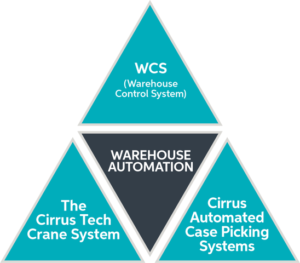

Warehouse Control System (WCS) Integration is a process that involves integrating hardware and software from multiple channels into a single warehouse control system solution. Cirrus Tech has years of experience in the implementation and integration of warehouse control systems to coordinate the automation equipment in your warehouse or distribution center. Cirrus Tech WCS Integration provides the bridge between your business systems and effective automation solutions.

Our WCS Integration plays a crucial role in ensuring various automation equipment works together to optimize productivity, maximize efficiencies and minimize costs. Our highly qualified team incorporates best-practice principles when implementing high-performing warehouse control system integration that maximize efficiency saving you time and money.

Our proven WCS Integration solutions are currently operating in beverage distributors encompassing every aspect of warehouse automation, including:

- Auto Receiving Product through ASN (Advanced Ship Notice)

- Tracking product throughout an automation solution

- Throughout the product verification process

- Pallet sizing stations

- Weight checking pallets

- In the shipment of product process